Photos from Jobsites

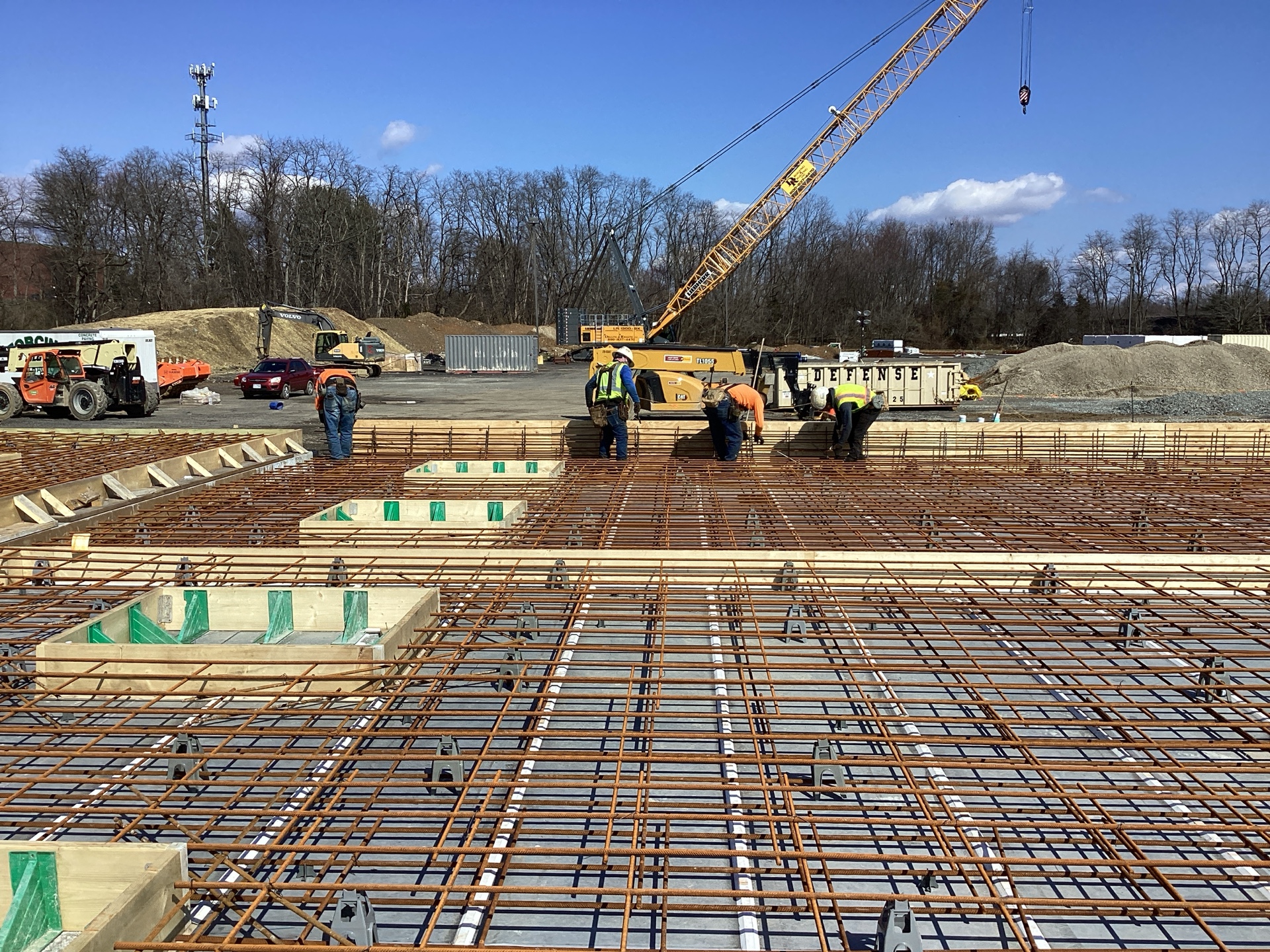

STRUCTURAL WELDED WIRE REINFORCEMENT PLACED IN FORMS FOR TILT-UP WALL PANELS

STRUCTURAL WWR BEING PLACED IN TILT-UP WALL PANEL FORMS WITH A SMALL PLACEMENT CREW AND A TELEHANDLER FIT WITH A SPREADER BEAM

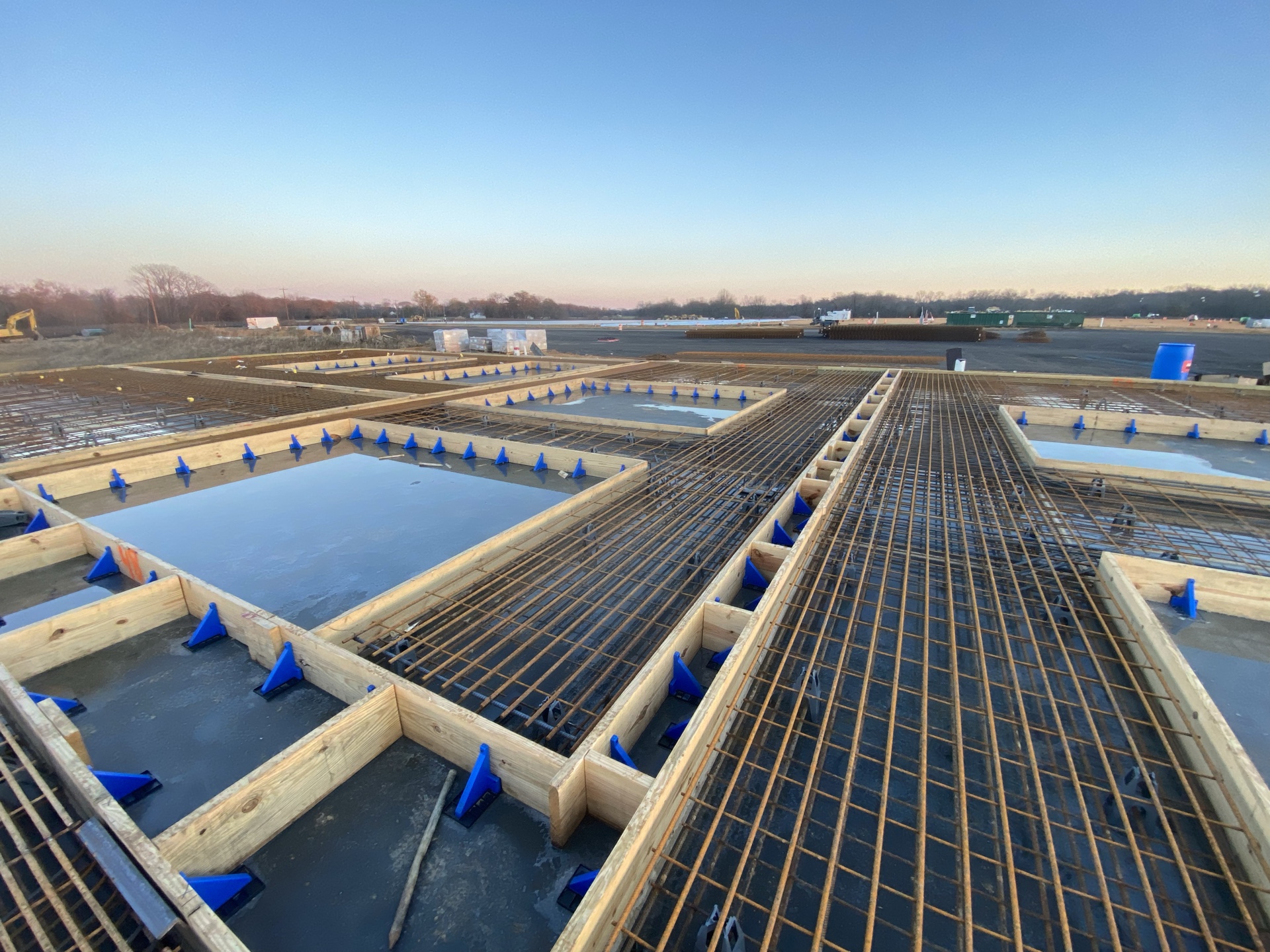

STRUCTURAL WELDED WIRE REINFORCEMENT FOR TILT-UP WALL PANEL CONSTRUCTION

STRUCTURAL WWR IN TILT-UP WALL PANEL FORMS. WWR EXHIBITS UNRIVALED TOLERANCE CONTROL AND EASE OF PLACEMENT.

STRUCTURAL WWR USED AS BOTH BONDED SLAB REINFORCEMENT AND BEAM SHEAR REINFORCEMENT IN A POST-TENSIONED CONCRETE PARKING DECK STRUCTURE

SEAMLESS INTEGRATION OF STRUCTURAL WWR WITH LOOSE DEFORMED REINFORCING BARS ON A TILT-UP WALL PANEL PROJECT.

STRUCTURAL WWR FOR A PRECAST INVERTED TEE GIRDER

A RUN OF TILT-UP WALL PANEL FORMING POPULATED WITH STRUCTURAL WWR

STRUCTURAL WWR PLACEMENT IN A HIGHWAY BRIDGE PRECAST GIRDER CASTING BED. WWR UTILIZED IN TOP FLANGE, STEM, AND BOTTOM FLANGE FOR ALL MILD STEEL REINFORCEMENT APPLICATIONS.

TELEHANDLER WITH SPREADER BAR COMBINED WITH A SMALL PLACEMENT CREW MAKES STRUCTURAL WWR PLACEMENT AN EXTREMELY QUICK AND EFFICIENT PROCESS.

WWR PRODUCED WITH NEGATIVE DEFORMATIONS (INDENTATION)

WWR PRODUCED WITH NEGATIVE DEFORMATIONS (INDENTATION)

STRUCTURAL DEFORMED WWR COMMONLY AVAILABLE IN DIAMETERS UP TO 5/8-INCH

WWR BENDING OPERATION AT THE MANUFACTURING PLANT

PLACING CONCRETE IN A CASTING BED POPULATED WITH STRUCTURAL WWR

STRUCTURAL WWR WELDING MACHINE USING ELECTRIC RESISTANCE WELDING PROCESS, FACILITATING UNRIVALED TOLERANCE CONTROL

EXPEDITED PLACEMENT OPERATION FOR STRUCTURAL WWR IN TILT-UP WALL PANEL FORMS

STAGING OF STRUCTURAL WWR BUNDLES FOR USE ON A TILT-UP WALL PANEL PROJECT

STRUCTURAL WWR USED AS U-STIRRUP SHEAR REINFORCEMENT IN A POST-TENSIONED CONCRETE BEAM

STRUCTURAL WWR IN PLACE FOR AN ISOLATED COLUMN SPREAD FOOTING

×

![]()